BPM White Papers and Case Studies

White Paper: Solving ICT Bottlenecks Through Offline Device Programming

Abstract As the manufacturing sector transitions to more complex electronic components, the efficiency and cost-effectiveness of programming semiconductor devices are of paramount importance. While In-Circuit Test (ICT) programming has been the traditional approach,...

Revolutionizing Device Programming: How BPM Microsystems Tackles OEM Challenges

Device Programming Pain Points for OEMs, and How BPM's Solutions Make Device Programming Fast, Easy, and Affordable Semiconductor device programming is a crucial step in the manufacturing process, one where Original Equipment Manufacturers (OEMs) often encounter...

5 Reasons Low-Cost Providers of Device Programmers Are Usually Not the Right Solution

Device programming machines and associated components are critical in the manufacturing and testing process of most electronic products. While it may seem tempting to initially save costs by opting for low-cost providers, several drawbacks often make these choices a...

Accelerating Progress: Transitioning from 7th to 9th Generation BPM Programmers – A Comprehensive Guide

Sun Sets on 7th Generation BPM Programmers In an era of transformative technological advancement, it's a common occurrence for some components to become obsolete due to scarcity or the evolution of technology. The same fate has befallen the 7th Generation BPM...

The Importance of Production Support, Losses Due to Unscheduled Downtime

In an electronics manufacturing production environment where a factory has automated machines and people, how would you calculate the cost if the process stops, including lost profit and losses due to unproductive people, equipment, and overhead? Calculating the cost...

How Much is Downtime Really Costing Your Electronics Manufacturing Business?

The Importance of a Production-Level Support Agreement in Electronics Manufacturing The rapidly evolving world of electronics manufacturing requires not only cutting-edge technology but also comprehensive support systems. Today's advanced production environments hinge...

Assembly Line Uptime, Inventory Management, Cost Per Device, and Superior First-Pass Yield: The Power of In-Socket Programming

Part 6 - Unveiling the Power of Offline In-Socket Programming In the grand finale of our series examining offline in-socket programming, we delve into its profound impact on maximizing assembly line uptime, enhancing inventory management, reducing cost per device, and...

Exploring Versatility: The Broad Range of Capabilities Enabled by Offline Programming

Part 5 - Unveiling the Power of Offline In-Socket Programming As we delve further into the advantages of offline in-socket programming, having scrutinized aspects of quality assurance (Part I), flexibility (Part II), ease of troubleshooting (Part III), and efficiency...

Harnessing Efficiency: The Power of In-socket Programming in Boosting Productivity and Reducing Costs

Part 4 - Unveiling the Power of Offline In-Socket Programming Having journeyed through the advantages of high-quality assurance (part I), flexibility (part II), and simplified troubleshooting (part III) offered by offline in-socket programming, we now turn our...

Easing Troubleshooting: The Role of Offline In-socket Programming in Enhancing Process Efficiency and Productivity

Part 3 - Unveiling the Power of Offline In-Socket Programming In our exploration of device programming thus far (See Part I, See Part II), we've addressed how it ensures high quality and offers unparalleled flexibility in streamlining production workflows. Now, we...

Part II: Power of Offline In-Socket Programming

Unveiling the Power of Offline In-Socket Programming to Maximize Assembly Line Uptime Part 2 - Embracing Flexibility: Unleashing the Power of Offline Programming in Streamlining Workflows In Part I, we appreciated how offline in-socket programming offers high-quality...

Unveiling the Power of Offline In-Socket Programming to Maximize Assembly Line Uptime

In an era where online connectivity is increasingly becoming a staple in our day-to-day life, the concept of offline programming, specifically offline in-socket programming, can seem somewhat unconventional. However, this proven process holds significant potential to...

White Paper: Enhancing Efficiency and ROI, A Comprehensive Guide to Offline In-Socket Programming for Electronics Manufacturers

Introduction: The Evolution of Device Programming Methods In the ever-evolving world of electronics manufacturing, the need for cost-effective and efficient in-socket programming solutions has become increasingly important. As technology continues to advance, new...

Easy Device Programming

Offline programming, while providing flexibility in the programming process, can be perceived as more complex due to the need for setting up and managing individual programmers. However, with the right solutions like those provided by BPM Microsystems, this process can be simplified, reducing the risk of errors and boosting efficiency.

Which Programming Method is Right for You?

Semiconductor devices are used in a wide range of electronic applications, from smartphones to industrial machinery. Programming these devices is a crucial step in their manufacturing process, allowing them to perform specific functions. There are several methods to...

White Paper: Semiconductor Device programming

Semiconductor device programming is a critical process in the manufacturing and development of electronic devices. It involves the programming of specific parameters and functionality into a semiconductor device, such as a microcontroller or memory chip, to ensure that it performs the desired tasks.

Programmable Devices for Modern Manufacturing

A programmable device is a piece of hardware that can be programmed to perform a specific set of tasks or functions. These tiny devices are often used in industrial and commercial settings, including manufacturing, healthcare, and automotive, to automate processes and improve efficiency.

Adapters: Understanding Socket Modules, D-Cards, and Socket Cards

“Socket” can mean different things depending on the context. Even in just electronics, “sockets” can mean more than one thing. When BPM uses the term “socket,” it is referring to the electro-mechanical interface between the BPM programmer and the programmable device.

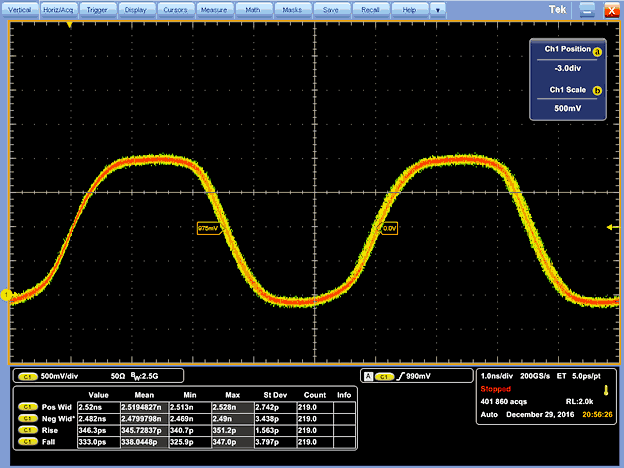

Up-Time, Accuracy, and Waveforms

BPM ensures accuracy and repeatability for device programming In three main ways: Auto-teach, Vision Alignment, and Job Automation. All programming systems are highly repeatable– once they are set up, they will reliably repeat their program (even if it isn’t perfect). The trick is to start with a perfect setup, resulting in repeatable, reliable, and accurate yield.

BPM API Delivers Quality and Traceability

BPWin API is a breakthrough in programming equipment connectivity, that digitizes the information being generated throughout your device programming operations, and makes it available where, when, and how you need it.

Off-line vs In-System Programming

In-system programming (ISP) allows some devices to be programmed after it’s soldered on the PCB board. This allows firmware updates and small data uploads, integrating programming and final test into a single step.

Offline Automated Programming vs Inline SMT Programming

A small segment of electronic manufacturing companies can use inline programming solutions effectively and economically, compared to off-line programming. A lack of flexibility, high cost, and the specter of obsolescence should raise questions about the long-term viability of Inline programming.

Integrate your ERP to BPM Programmers with API

BPWin API is a breakthrough in programming equipment connectivity, that digitizes the information being generated throughout your device programming operations, and makes it available where, when, and how you need it.

Universal Device Programmers

Some solutions are more “universal” than others There are quite a few device programming solutions that describe themselves as “universal.” You would think everyone is using the term “universal” the same way. Think again. “Universal” as an adjective, means: “of,...

How to Program In-House, Part II

To learn how to Program in-House, we’ll cover Benchmarking to determine which system you need to bring programming under your roof. Then we’ll show you how you can start making positive ROI in weeks, not months or years.

Disaster Recovery for a Modern Manufacturing Operation

It’s not a matter of “if” things go wrong. It’s a mathematical certainty. If 2020 has taught us anything, it’s prudent to be ready for just about anything. With a little forward planning, you should keep production moving. BPM’s systems are built to grow with your business; they have programmers that are still operating daily after 15 years or more. Contact your preferred Programming Center and BPM Microsystems to develop a disaster plan in advance.

How to Program In-House, Part I

In our example, we’ve got two programmable devices on our board: a TSOP and a QFP programmable device. The TSOP has 1200 Kilobytes of data; the QFP has 1 Gigabyte (which makes in-line or on-board programming a bad option).

Programming Devices— where no repairman has gone before

Whether it’s a sensor on an anti-lock brake assembly or a telemetry chip on a satellite, there are increasing numbers of programmed devices where failure isn’t an option; either it’s difficult or impossible to replace in the field, or failure means the potential loss of irreplaceable life and equipment (or both). When it comes to programming a mission-critical antifuse device, who is the only authorized vendor on which Microsemi relies? BPM Microsystems.

3901 Job Changeovers– Fast and Easy

Job changeovers can be a major hassle, but they don't have to be. In this live demonstration, the Sales Guy (Colin Harper) does a job changeover in 3 minutes (and almost half of that he's talking and not working). BPM automated programmer job changeovers are fast and...

Video: Bring your mission-critical programming in-house

Smaller OEMs, while perhaps having many of the same needs as the Automotive guys, were constrained by limited resources. As their programming needs outgrew their ability to produce on manual systems, the only option was to outsource to the programming houses or ship their component manufacturing off-shore. Then came the perfect storm of 2019: a crippling trade war, followed by a growing pandemic.

Bring your mission-critical programming in-house for less than the cost of outsourcing AND maintain control of your IP

Moore’s law (Moore’s law is the observation that the number of transistors in a dense integrated circuit doubles about every two years (see https://en.wikipedia.org/wiki/Moore%27s_law) )states integrated circuits double in both speed and number of circuits roughly every two years. As programmable devices become smaller, denser, and more complex, most machines that program those devices have become more expensive, and require experienced technicians to operate, maintain and troubleshoot.

Signal Integrity

Not all programming solutions are the same. If quality and maximum device life are important, it’s imperative to know what to look for. When evaluating a programming solution, ask about signal integrity. Review this white paper for helpful tips.

Are Market Forces Beyond Your Control Keeping You Up at Night?

OEMs recognize the risk in outsourcing critical components, such as programmed devices, to off-shore suppliers. They are looking more closely at options that reduce their reliance on forces beyond their control in a way that reduces costs and speeds go-to-market. Download the white paper now.

What is the Best Way to Get Devices Programmed?

There are lots of ways to get your data on devices, and there’s no one "Best" programming that is always better than another. Options that are available today: In-House Off-Line Programming Program at ICT (in-circuit test) Program with In-System Programming (ISP) at...

Top 6 Reasons you should bring your programming In-house

If you are currently outsourcing your device programming, here's 6 reasons you may want to reconsider (and if you're already programming in-house, here are 6 reasons to feel good) 6. Security It may sound simple, but just having your program in your facility is a...

CSP Programming Strategies for the C-Suite

Originally published in Vol. 18, No. 2 of Global SMT & Packaging Magazine Good things come in small packages, but small packages can be tricky and costly to handle. The trend for higher density devices and smaller package sizes creates a unique set of challenges...

Mastering eMMC Device Programming

Over the past decade, the demand for high-density, nonvolatile memories with a small footprint has increased dramatically. Two of the most popular markets driving this demand are handheld devices and automotive. Demand for handheld devices continues to drive the research for high-density, low power, low-cost, high-speed, nonvolatile memories while maintaining a small footprint. NAND-type flash memory is the perfect match for such a market. The increased consumer demand for high-tech features in automobiles, such as infotainment systems, is also a big driver of demand for high-density NAND-based devices.

BPM Microsystems Releases White Paper on Device-Driven Serialization

In the device programming industry, serialization is the process of writing unique data to each programmed device. It can be used to program basic numeric serial numbers to a single device address and can also be used to program more complex data such as MAC addresses, encryption keys, GUIDs and randomization seeds to several device addresses on each device.

Understanding NAND Flash Factory Programming

During the manufacturing of electronic systems, blank non-volatile devices must often be programmed with initial data content. This allows the target system to get up and running, and is referred to as “factory programming,” “factory pre-programming,” or “bulk programming.” Generally, this is a very straightforward process that has been in place in the industry for many years. However, with NAND flash the process is more difficult.